Product Specifications of Dual Fuel Kit 1010 kVA / 808 kW DG Sets

| Dual Fuel Kit 1010 kVA / 808 kW | |

|---|---|

| Specification | Details |

| Power Rating | 1010 kVA / 808 kW |

| Gas Substitution Capacity | Up to 70% depending on load and gas |

| Supported Gas Types | CNG, PNG, LPG, Biogas |

| Required Gas Pressure | 3kpa to 10kpa |

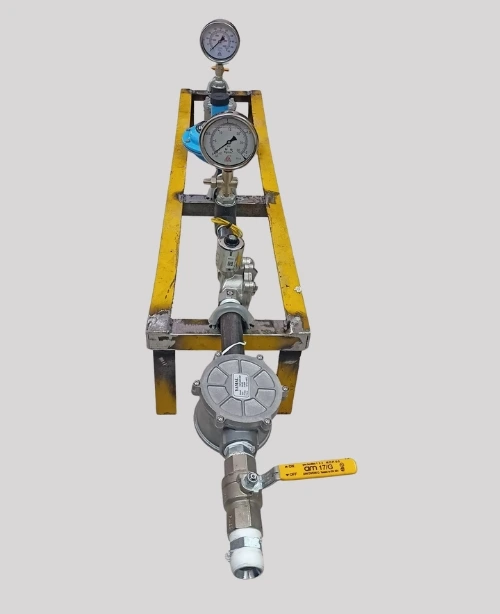

| Mixer Type | High-efficiency, heavy-duty Venturi mixer |

| Regulator Type | Industrial 2-stage gas pressure regulator |

| ECU Technology | Microprocessor-controlled smart fuel management |

| Safety Features | Gas cut-off, backfire Protection, PRVs, leak detection |

| Material Quality | SS tubing, Aluminium alloy body, anti-corrosive design |

The Aceget Duel Fuel Kit for 1010 kVA / 808 kW DG Sets is an advanced and fully optimized solution that provides support to commercial, industrial, and transportation users. It’s a combination of diesel and natural gas. This helps industries by minimizing costs, improving efficiency, and adopting eco-friendly behaviour processes.

The Aceget is established around non-intrusive technology that needs no internal changes to the engine or alternator. This makes installation quick, clean, & fully reversible, allowing users to maintain their DG’s original integrity and manufacturer standards. The kit intelligently switches back to 100% diesel mode if gas supply drops or if any safety interlock is triggered, ensuring uninterrupted power at all times.

We aim to provide cost-effective, emission control, fuel consumption, & meet modern sustainability standards. The 1010 kVA / 808 kW generators are the perfect choice for commercial, industrial, and transportation users. Fuel cost is one of the biggest expenses for these types of users. We help you minimise your extra costs on fuel with our dual fuel conversion kit. Our field technicians ensure better output without making any changes to the generator’s original structure.

Our aim is to provide the perfect balance of cost, emission control, fuel consumption, and genset’s performance. The 125 kVA/100 kW generators are the ideal choice for hospitals, institutions, hotels, and other industrial sites. Fuel cost is one of the biggest expenses for these types of users. We help you to reduce your extra expenditure on fuel with our dual fuel conversion kit. Our field technicians ensure better output without making any changes on the generator’s original structure.

Key Features of the Dual Fuel Kit

Our 1010 kVA / 808 kW dual fuel kit system is organised to survive high temperatures, vibration, and continuous usage.

- Using Aceget’s Dual Fuel Kit reduces the utilisation of Diesel

- It Everlasting generator’s life

- Reduced CO₂ & particulate emissions

- Maintenance Cost is very low.

- Lowering noise, which leads to an eco-friendly environment

- Eliminating engine detonation

- Stable performance at partial loads

- Appropriate Engine Brands or models

- Fuel Cost reduced by per km/h.

Key Features and Benefits of using Aceget’s Dual Fuel Kit

- Using Aceget’s Dual Fuel Kit reduces the utilisation of Diesel

- It Everlasting generator’s life

- Reduced CO₂ & particulate emissions

- Maintenance Cost is very low.

- Lowering noise, which leads to an eco-friendly environment

- Eliminating engine detonation

- Stable performance at partial loads

- Appropriate Engine Brands or models

- Fuel Cost reduced by per km/h

Applications and Brands Compatibility

The AceGet Dual Fuel Kit for 1010 kVA / 808 kW DG Sets is widely utilized among industries that demand reliable and cost-efficient power, involves manufacturing plants, commercial complexes, hospitals, data centers, hotels, mining operations, construction sites, & other continuous-operation facilities. The system is fully fitted with all major generator brands like Cummins, Caterpillar, Kirloskar, Perkins, MTU, Mahindra Powerol, Greaves, Ashok Leyland, & Volvo Penta, with standard OEM control panels like Deep Sea, Woodward, ComAp, & Schneider/L&T. This broad compatibility make sure seamless integration, stable performance, and high diesel savings across diverse industrial environments.

Installation Process

- Site inspection: firstly, they visit your site and see whether the place is suitable for a Diesel generator or not.

- Components Choose: after inspection, they choose best best-suited dual fuel kit components.

- Gas pipeline readiness: it ensures a perfect size, tested, & safe route for safe kit installation.

- Kit installation: after the gas pipeline reading, they install a dual fuel kit at your place.

- ECU calibration & testing: verify ECU monitoring, calibration & testing.

- Operator training: at last, do check the overall performance of the installed kit.

Why Choose Our Dual Fuel Kit?

There are several reasons to choose the Dual Fuel Kit, which are:

- OUR Dual kit has that much potential that deliver high savings on diesels

- Highly qualified components with intelligent ECU control

- It cuts off operating costs, emissions & ensures uninterrupted power

- Have automatic switching and a robust protection feature